Stick-Built and Curtain Wall Systems

Curtain walling has been very successfully integrated into an exceptionally wide range of projects and different types of curtain wall system have evolved to provide tailored solutions.

Here’s a brief analysis of the most common types of curtain walling.

Stick-Built Curtain Wall System

The most established and traditional method of curtain wall construction. Stick-built systems are manually assembled piece-by-piece on-site. Mullions (vertical elements) and transoms (horizontal elements) are installed first, followed by glazing panels.

Stick-built curtain walls offer the widest possible project customisation and adaptability and are the ideal solution when a project potentially requires component adjustability during installation, allowing for any last minute on-site design changes.

Designers enjoy optimal technical and aesthetic flexibility with stick-built systems, thanks to a huge range of shapes, sizes, infills and additional elements.

Low to mid-rise buildings are particularly suited to stick-built solutions, which are the curtain wall system of choice when cost-efficiency is paramount.

Kawneer’s stick-built curtain wall systems include the AA®100 50mm Curtain Wall System and the AA®110 65mm Curtain Wall System.

Application example – Kawneer stick-built curtain walling accommodated a 9.5mm triple-laminated glass fin detail for solar shading on an impressive curved frontage at Stafford College Skills & Innovation Centre.

Unitised Curtain Wall System

A unitised curtain wall is a modular method of construction. Each panel is a self-contained module (usually one floor tall and one bay wide), integrating glazing, insulation, and aluminium framing.

Unitised systems are pre-assembled in factory-controlled environments into large panels, then shipped and installed on-site.

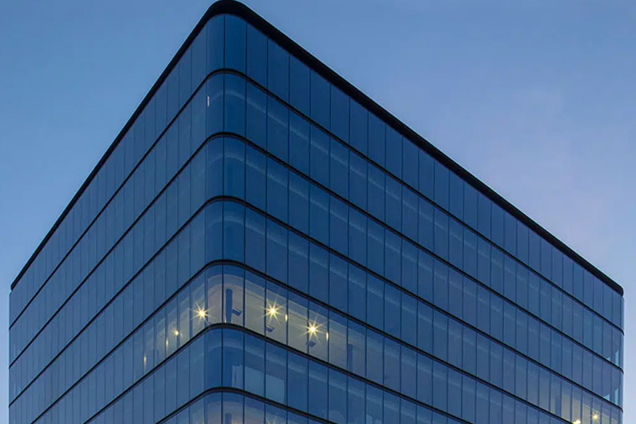

High-rise, multiple-storey structures are the perfect application for a unitised system, particularly when site access is limited and the best installation solution is to crane-in curtain wall modules. Weather dependency is also reduced, enabling the construction programme to continue when it might otherwise be delayed. These practical advantages will often more than offset the initially higher cost of unitised systems.

The repetition and scalability of uniform modular panels affords the designer a high-tech building aesthetic, further enhanced by factory quality controls that ensure unitised modules achieve high-precision alignment on site and a totally consistent and reliable finish and performance.

Buildings with higher levels of building movement and heavier infills also greatly benefit from unitised systems, which have capacity to cope with these key project demands.

Kawneer’s unitised curtain wall solutions consist of the AA®201 Unitised Curtain Wall and the AA®265 Unitised Curtain Wall.

Application example – Kawneer unitised curtain walling was used for a world-class medical facility in Manchester.